Firefighters are continuously exposed to particulates and polycyclic aromatic hydrocarbons that may heighten the likelihood of cancer. This is why they wear a self-contained breathing apparatus (SCBA) during fire suppression and overhaul—to protect the respiratory tract, which is vulnerable to toxic combustion products that are commonly found in smoke and soot.

To mitigate these risks, the Department of Homeland Security Science and Technology Directorate’s First Responders Group, North Carolina State University’s (N.C. State) Textile Protection and Comfort Center and LION First Responder PPE, Inc. are designing a new Smoke and Particulate Resistant Structural Turnout Ensemble prototype that takes protection from smoke and soot infiltration to the next level.

In 2010, the World Health Organization’s International Agency for Research on Cancer named the occupation of firefighting as possibly carcinogenic [Link no longer valid, http://www.cdc.gov/niosh/firefighters/ffcancerstudy.html] to humans. The results of several studies indicated at the time that firefighters experience a 50 percent increased risk of testicular cancer, a 30 percent elevated risk of prostate cancer, and a 21 percent elevated risk of non-Hodgkin lymphoma compared to other professions.

Firefighters use a protective hood that interfaces with several ensemble parts, including the SCBA face piece, helmet, hoods and the turnout gear’s coat collar. Even when all of these ensemble items are functioning correctly, portions of the head, neck, torso, legs and face still accumulate soot and particles.

The effort to design this new ensemble prototype is taking two different approaches. The first focuses on using a retrofit compatible design that would provide the current standard turnout gear moisture barrier with improved interfaces. This would provide the required level of protection without causing a significant change in donning/doffing or thermal comfort for the firefighter. The second approach is to use a bib overall-type design that provides additional torso protection, but may impact the wearer’s thermal comfort.

N.C. State carried out initial aerosol testing of the retrofit concept on June 24, 2016, at RTI International, located at Research Triangle Park in North Carolina.

The testing chamber that produces the aerosol houses an open-jet recirculating wind tunnel. It features a 7-foot diameter, 40-hp vane-axial fan centrally located in the sealed room, which measures 28 feet by 50 feet. It can produce wind speeds up to 40 mph within a 6-foot diameter test section. The controlled environmental conditions combined with the recirculating, high-efficiency filtration system and ambient air purging system ensure the parameters remain constant for the duration of testing.

The test subjects donned the ensemble and performed a series of exercises replicating response activity inside a closed chamber, while they were exposed to fluorescent aerosol particles. After 30 minutes of exposure, the test subject removed the test garment, either a current commercially available off-the-shelf (COTS) turn-out ensemble or the retrofit design prototype of the Smoke and Particulate Resistant Structural Turnout Ensemble. The results provide a visual assessment of the locations of particulate deposits on the test subject’s body, providing information for where the leakage occurs and how much particulate has made its way onto the firefighter’s skin.

In the testing chamber, the individual was subjected to a high-level concentration of silica powder particles tagged with a fluorescent tracer having a particle size ranging from 0.1 to 10 microns. The test subject performed a variety of different movements over the course of a half hour, while particles were blown through the chamber at 10 mph. This included standing, lying down, twisting and spreading out their arms.

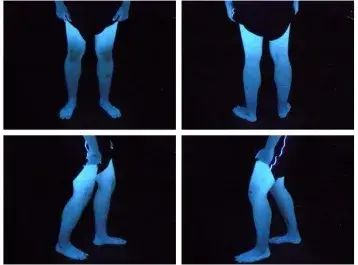

Following the exposure, the exterior of the garment was then wiped down and the ensemble carefully removed to avoid exterior particle transfer to the interior. Using black light photography of the test subject before entering the chamber provides a baseline comparison of where the inward leaks occur after the testing. The following pictures provide an example of test results and where the infiltration of florescent particles was detected. These photos were from the test report conducted at RTI at the request of the International Association of Fire Fighters (IAFF) in January 2015 on a worn, but serviceable standard turnout ensemble.

The photos serve as a baseline guide on how standard turnout ensembles perform until we can get further test results on our baseline system.

The green areas indicate where the florescent dyed particulates accumulated on the neck and jaw line of the test subject wearing standard firefighter personal protective equipment (PPE).

These results show the absence of particulates on the neck, shoulders and jaw line of the test subject using the Smoke and Particulate Resistant Structural Turnout Ensemble prototype when used with one of the COTS particulate barrier hoods that are now available on the market.

The green areas signify the deposits and buildup of florescent dyed particulates on the legs of the test subject using the standard firefighter PPE.

These images show the relative absence of particulate deposits on the legs of the test subject wearing the Smoke and Particulate Resistant Structural Turnout Ensemble retrofit design prototype.

The black light pictures illustrate just how common it is for smoke and soot to penetrate the standard firefighter PPE ensemble at the interface areas. This puts firefighters at potential health risks due to long-term particulate and vapor exposure.

By decreasing the potential for chronic skin exposures to toxic airborne compounds, this prototype ensemble and the technologies developed during this research will help to improve firefighter well-being and safety. The key challenge is designing an ensemble turnout uniform that protects firefighters from particulates, while avoiding added weight or restrictions to their movements.

This project is scheduled to be completed in early 2017 with the goal of providing firefighters with a turnout ensemble with integral resistance to smoke and other particulates without requiring additional equipment. Following National Fire Protection Association certification, the prototype will ultimately be transitioned into a commercial product available from LION First Responder PPE, Inc.

For more information, please email us at first.responder@dhs.gov.